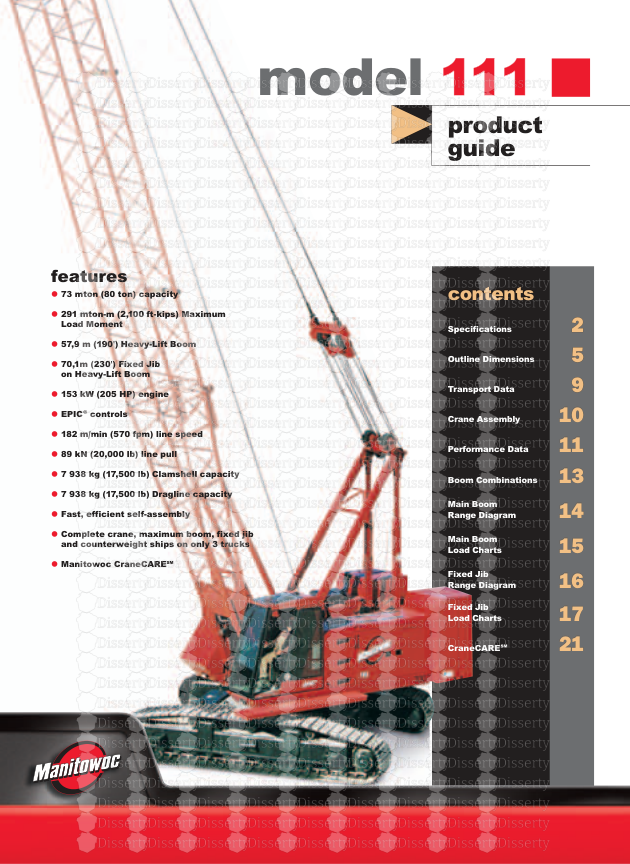

model 111 product guide features • 73 mton (80 ton) capacity • 291 mton-m (2,10

model 111 product guide features • 73 mton (80 ton) capacity • 291 mton-m (2,100 ft-kips) Maximum Load Moment • 57,9 m (190') Heavy-Lift Boom • 70,1m (230') Fixed Jib on Heavy-Lift Boom • 153 kW (205 HP) engine • EPIC! controls • 182 m/min (570 fpm) line speed • 89 kN (20,000 lb) line pull • 7 938 kg (17,500 lb) Clamshell capacity • 7 938 kg (17,500 lb) Dragline capacity • Fast, efficient self-assembly • Complete crane, maximum boom, fixed jib and counterweight ships on only 3 trucks • Manitowoc CraneCARESM contents Specifications 2 Outline Dimensions 5 Transport Data 9 Crane Assembly 10 Performance Data 11 Boom Combinations 13 Main Boom Range Diagram 14 Main Boom Load Charts 15 Fixed Jib Range Diagram 16 Fixed Jib Load Charts 17 CraneCARESM SM 21 Hydraulic reservoir capacity is 568 l (150 gal) and is equipped with breather, dipstick, clean out access, and internal diffuser. Each function is equipped with relief valves to protect the hydraulic circuit from overload or shock. Replaceable, spin on ten micron (absolute) full flow line filter is furnished in the hydraulic circuit. All oil is filtered prior to return to the hydraulic reservoir. Hydraulic system also includes pump transmission disconnect clutch & hydraulic oil cooler. Drums Two identical winches 483 mm(19") diameter and 543 mm (21-3/8") wide are driven by independent variable displacement axial piston hydraulic motors through planetary reduction mounted on separate front and rear shafts with anti-friction bearings. Powered lowering standard with automatic (spring applied, hydraulically released) multi-disc brakes and drum rotation indicators. Optional free-fall for front and/or rear drum(s). Includes internally expanding clutch assembly and external contracting band brake manually applied by foot pedal with locking latch in operator’s cab. Operator may select free-fall or powered lowering mode using a selector switch. Note: Free-fall drums are required for clamshell/dragline operations. Optional auxiliary (third) hydraulic powered drum rated at 66,7 kN (15,000lb) line pull for third line over upper boom point, mounted on front of rotating bed. Includes third sheave for boom top wire rope guide and boom butt wire rope guide. Optional auxiliary drum rated at 66,7 kN (15,000 lb) line pull as described above, mounted in boom butt. Optional auxiliary drum preparation includes electric wiring and hydraulic plumbing. Optional bolt-on liftcrane lagging. Optional bolt-on clamshell lagging. Optional wire rope for various applications (see page 12). System Front Drum Rear Drum Boom Hoist Swing System Left Crawler Right Crawler kg/cm2 (psi) 422 (6,000) 422 (6,000) 422 (6,000) 316 (4,500) 387 (5,500) 387 (5,500) lpm (gpm) 284 (75) 284 (75) 155 (41) 155 (41) 155 (41) 155 (41) Upperworks Engine Cummins 6CT8.3 diesel, 6 cylinder, 153 kW (205 BHP) @ 2200 governed RPM. Manually operated disconnect clutch for cold weather starting. Multiple hydraulic pump drive transmission provides independent power for all machine functions. Optional: consult factory for other available engines. One 340 l (90 gal) capacity diesel fuel tank, mounted on rear of upperworks, with level indicator in operator’s cab. Two 12 volt maintenance-free, Group 8D batteries, 1155 CCA at -18°C (0° F), 12 volt starting and 130 amp alternator. Controls Modulating electronic-over-hydraulic controls provide infinite speed response directly proportional to control lever movement. Controls include Manitowoc's exclusive EPIC® Electronic Processed Independent Controls system providing microprocessor driven control logic, pump control, on-board diagnostics, and service information. Block-up limit control is standard for hoist and whip lines. Integrated Load Moment Indicator system (LMI) is standard for main boom, upper boom point, and fixed jib. “Function cut-out” or “warning only” operation is available via a keyed switch on the LMI console. Travel and swing alarms are standard. Hydraulic System Six high-pressure piston pumps are driven through a multi-hydraulic pump transmission. These six pumps provide independent "closed loop" hydraulic power for front drum, rear drum, boom hoist system, swing system, and both left and right crawler operation. 2 specifications model 111 Boom Hoist Independent two-drum boom hoist with grooved drums including 131,1 m (430') of 15,8 mm (5/8") diameter wire rope reeved with 10 parts of line. Drums are powered by a fixed displacement hydraulic motor coupled to an internal brake and planetary gearbox equipped with ratcheting pawl. Boom hoist speed: raise 57,9 m (190') full main boom from 0˚- 81.5˚ in 80 seconds. Swing System High strength fabricated steel alloy rotating bed is mounted on 1,64 m (64-3/4") diameter turntable bearing. Independent swing powered by a fixed displacement hydraulic motor coupled to a planetary gearbox with internal brake. 360˚ positive swing lock. Swing system maximum speed: 3.6 rpm. Counterweight Total standard upper counterweight assembly is 19 960 kg (44,000 lb) consisting of one inner 12 930 kg (28,500 lb) counterweight and one outer 7 030 kg (15,500 lb) counterweight. During self-assembly, the crane boom butt and hoist are used to lift the counterweights up onto lugs at the rear of the rotating bed upperworks via a tethered remote control. The counterweights are then secured in place by two hydraulic pins for fast, safe assembly. Optional Series B counterweight system consisting of one 2 585 kg (5,700 lb) center counterweight box and two carbody counterweights at 1 815 kg (4,000 lb) each. Includes connecting pins, retaining bolts, and washers. Operator’s Cab Fully enclosed and insulated steel module mounted to the left front corner of rotating bed. Module is equipped with sliding door, large safety glass windows on all sides and roof. Signal horn, cab space heater, front and roof windshield wipers, dome light, sun visor and shade, fire extinguisher and air circulating fan are standard equipment. Optional air conditioning for operator’s cab. Optional nylon protective window covers for operator’s cab. Attachments No. 111 Heavy Lift Main Boom The base liftcrane comes standard with a 12,2 m (40') No. 111 Basic Heavy-Lift tubular chord boom consisting of 6,4 m (21') butt and 5,8 m (19') open throat top with four 50,8 cm (20") diameter roller bearing sheaves on one shaft. The basic heavy-lift boom also includes a boom angle indicator, pendant rigging, cushioned boom stops, and automatic boom hoist stop. 4,7 m (15' 6") gantry and telescopic backhitch with sealed anti-friction bearings and nylon sheaves in gantry and equalizer system. Optional No. 111 3,0 m (10'), 6,1 m (20'), and 9,1 m (30') main boom inserts with pendants. Optional detachable upper boom point with one 50,8 cm (20") roller. No. 111 Fixed Jib Optional No. 111 Basic Fixed Jib 9,1 m (30') length. Consisting of 4,6 m (15') jib butt and 4,6 m (15') jib top with 3,7 m (12') jib strut, pendants and backstay. Optional No. 111 Fixed Jib Inserts 3,0 m (10’). Utilize up to three fixed jib inserts in combination with the No. 111 Basic Fixed Jib for total lengths of 12,2 m (40'), 15,2 m (50'), and 18,3 m (60'). 3 specifications model 111 US Standard Tool Kit – Includes all US tools required for routine maintenance (with the exception of a torque wrench). Hydraulic Test Kit – Required to properly analyze the performance of the EPIC® control system. Service Interval Kits – For the regularly scheduled maintenance of general crane operations. Lighting Packages – Consult Factory for available options. Special Paint – In colors other than Manitowoc standard red and black. Special Customer Decals – Custom vinyl decal(s) of name and/or logo from artwork supplied by customer. Export Packaging – Basic crane, boom and jib sections. Additional Applications Clamshell: Includes tagline, boom point roller guide, two 51,9 cm (20-7/16") laggings for 22 mm (7/8") wire rope, and pressure rollers for both front and rear drums. Dragline: Includes fairlead, boom point roller guide, two 51,9 cm (20-7/16") laggings for 22 mm (7/8") wire rope, and pressure rollers for both front and rear drums. Pile Driving: Includes shaft for attachment of fixed pile leads. Lowerworks Carbody Steel fabricated carbody with wide flange wings for mounting to crawler side frames. Two variable displacement travel motors driven through planetary gearboxes provide narrow-profile mounting within the crawler modules. Crawlers Crawler assemblies are 5,9 m (19' 4") long with 91,4 cm (36") wide triple grouser crawler pads. Excavator-type crawlers have full counter-rotation capability. Hydraulic extension/retraction of crawler assemblies with tethered remote control. Maximum ground speed of 2,4 kph (1.5 mph). Optional crawler handling package includes a high capacity wire rope guide mounted in the boom butt, sheave frame that attaches to the boom butt, single sheave 20 mton (22 ton) self-assembly block for 22 mm (7/8") or 31 mm (1-1/4") wire rope, and four 1,8m (6' 0") nylon eye round slings. Optional Equipment Blocks and hooks – 11 mton (12 ton) Swivel hook with 336 kg (740 lb) weight ball 11 mton (12 ton) Non-swivel hook with 336 kg (740 lb) weight ball 27 mton (30 ton) hook block with 2 sheaves, 22 mm (7/8") wire rope grooves 36 mton (40 ton) hook block with 2 sheaves, 22 mm (7/8") wire rope grooves 45 mton (50 ton) hook block with 3 sheaves, 22 mm (7/8") wire rope grooves 54 mton (60 ton) hook block with 3 sheaves, 22 mm uploads/Ingenierie_Lourd/ 111-product-guide.pdf

Documents similaires

-

45

-

0

-

0

Licence et utilisation

Gratuit pour un usage personnel Attribution requise- Détails

- Publié le Dec 21, 2022

- Catégorie Heavy Engineering/...

- Langue French

- Taille du fichier 3.2471MB